Silicon carbide (SiC) substrates have gained a lot of attention in the semiconductor industry, especially in high-power electronic devices. Here are some of the key advantages of using SiC substrates in such applications:

1.High Thermal Conductivity: SiC has a thermal conductivity that is 3-5 times higher than that of silicon (Si) substrates. This allows for faster heat dissipation and helps in keeping the device temperature low.

2.High Breakdown Voltage: SiC substrates have a high breakdown voltage, which allows them to withstand high electric fields. This allows for the development of devices that can operate at high voltages and currents, making them ideal for high-power applications.

3.High Electron Mobility: SiC has a higher electron mobility than Si, which allows for the development of devices that can operate at higher frequencies. This is important in applications such as RF amplifiers and high-frequency switching circuits.

4.Wide Bandgap: SiC has a wide bandgap, which allows for the development of devices that can operate at higher temperatures. This is important in high-temperature applications such as power electronics and aerospace.

5.Reduced Power Losses: SiC substrates have a lower on-resistance and switching losses than Si substrates. This allows for reduced power loss and improved efficiency in high-power electronic devices.

Overall, SiC substrates offer several advantages over traditional Si substrates in high-power electronic devices. With continued research and development, SiC substrates are expected to further improve performance and efficiency in a wide range of applications.

What is CMP?Chemical Mechanical Planarization (CMP) is a critical process in semiconductor manufacturing used ...

Dislocations are a significant factor affecting the quality and performance of 4H-SiC (Silicon Carbide) single...

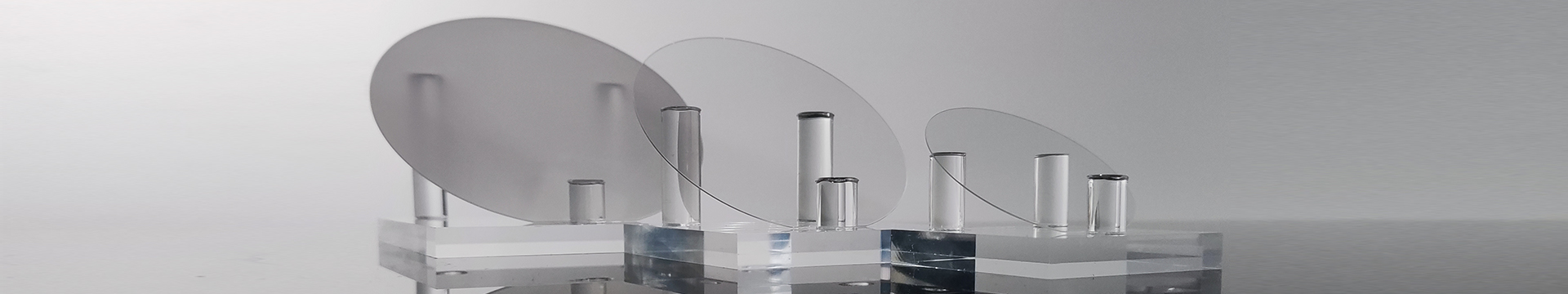

In the modern field of science and technology, Silicon Carbide (SiC) serves as an important functional materia...